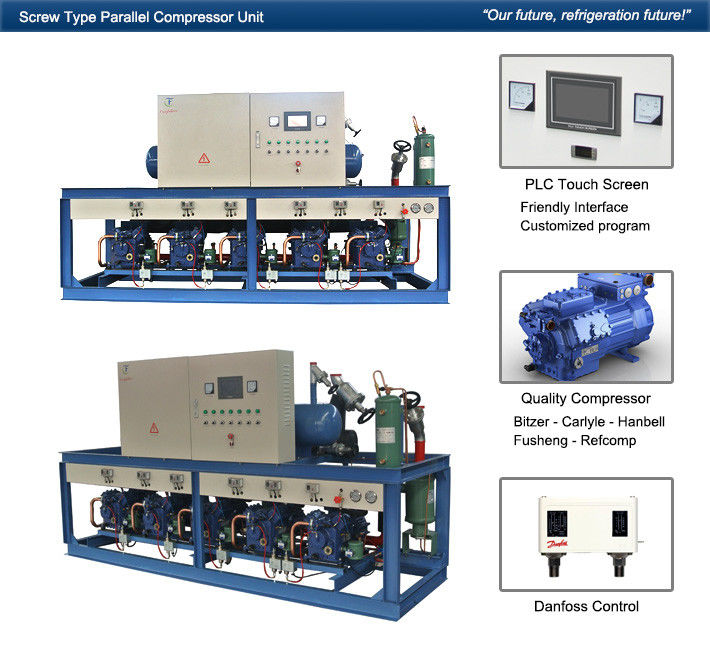

Cold Room Condensing Unit Cold Storage Unit For Vegetable Storage

Product Details:

| Place of Origin: | China |

| Certification: | ISO 9001:2008, CE, CCC, QS |

| Model Number: | OBBL2-180L |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | nigotiation |

| Packaging Details: | Plastic film + Plywood case |

| Delivery Time: | 20 days |

| Supply Ability: | 100 units per month |

|

Detail Information |

|||

| Compressor Brand: | , Carlyle, Danfoss, Copeland, Bock, Hanbell, Fusheng, Etc. | Cooling Type: | Water Cooled |

|---|---|---|---|

| Refrigerant: | R404a, R22 | Voltage: | 380V/3P/50Hz, 220V/1P/60Hz |

| Use: | Cold Room, Blast Freezer, Cold Chain Logistic, Pharacy, Refrigeration | Evaporating Temperature: | 10~-15℃, -15~-35℃, -30~-50℃ |

| Condensing Temperature: | 35℃ | Compressor Type: | Screw Type |

| Highlight: | compressor condensing unit,industrial water chiller units |

||

Product Description

Can used for multiple refrigerant R404a, R507, R407C, R22.

- The units are equipped with world famous brand high quality compressor and components, following the latest design, the perfect combination provides a safe and reliable system.

- We produce our compressor racks with world famous components and the world lastest technology. Each compressor rack is standardly equipped with phase loss protection, reverse phase order protection, over voltage/lack voltage protection, oil pressure protection, high/low pressure protection, motor over load protection, etc. This would enable our compressor racks to avoid frequently startup/off and provide a stable and reliable performance to end user.

- High efficiency oil separating system. When power is on, there is no need to add lubricating oil, the standard provided oil heater, oil temperature controller and oil level switch, etc. can protect the function.

- The PLC controller is a standard provided component. It can automatically decide the compressor quantity to be used based on actual need of refrigerant capacity, average the running time between each compressor, save the power. All of these will guarantee an over 30% longer usage than single compressor condensing unit.

- It has a unique low environment condensing pressure monitor system which guarantees a stable functioning when there is a low ambient temperature, lack of oil feeding or oil flow warnin

- High efficiency gas liquid separator is used, with a unique pipeline design, it can effectively minimize the possibility of liquid strike.

- The “Pressure Vessel Certificate” approved reservoir is provided as well as the safety relief valve.

- Fault isolation device is served so that when a certain compressor breaks down, the rest of the unit can keep running appropriately, making sure that client has enough time for repair and replacement.

| High Temperature Reciprocating Type Parallel Compressor Unit Standard Configuration | |||

| 1 | Parallel unit components | 7 | Gas-liquid separator |

| Strong metal frame | |||

| Lifting ring | 8 | Control & Protection | |

| Cushion | Compressor high/low pressure controller | ||

| 2 | Reservoir components | Electrical over current protector | |

| 28 bar safety valve | Low pressure sensor | ||

| Inlet/outlet stop valve | Separate breaker and heater protector | ||

| Reservoir sight glass | PLC control with color touch screen | ||

| Pipeline sight glass | |||

| Filter drier barrel, with filter core | 9 | Liquid feeding manifold and return manifold components | |

| Stop valve for filter barrel outlet | Quantity follow catalog | ||

| 3 | Discharge components | Manifold uses hard tube | |

| Oil separator | |||

| Oil separator outlet stop valve | 10 | Other | |

| Shock absorption tube | Compressor pressure gauge | ||

| Prepair valves are mounted on each manifold | |||

| 4 | Oil line components | Insulation materials for suction pile, subcooler and cooling tube | |

| Reservoir(with oil sight glass) | Compressor suction stop valve | ||

| Reservoir inlet/outlet stop valve | |||

| Oil single direction valve | 11 | Optional configures | |

| Oil line outlet filter | Refrigerant R22, R404a | ||

| Oil line ball valve | Vertical or horizontal reservoir | ||

| Oil level controller | Liquid feeding manifold and return manifold components | ||

| 5 | Single compressor components | Cooling type: air cooled, water cooled, evaporative cooling | |

| Suction/discharge stop valve | Other brand compressor and valves | ||

| Compressor shockwave cushion | Electrical or manual oil level controller | ||

| Suction filter barrel, with filter core | |||

| Oil sight glass | 12 | Other components | |

| Oil pressure controller(for oil pump fabrication) | Compressor exhaust muffler | ||

| Crankcase heater | High pressure sensor | ||

| Compressor fan | Heat recovery device | ||

| Compressor spray cooling | Hot gas defrost fuction | ||

| Refrigeration oil | |||

![]()

![]()

![]()

Want to Know more details about this product